0,00 zł

Welder Inverter MIG/MAG MMA/TIG Lift Paton StandardMIG-250

PRICE ON REQUEST

- Welding methods: MMA, MIG-MAG, TIG LIFT

- Welding current: 12A-250A, power supply 230V

- Warranty: 5 years, also for companies

- Duty cycle: 45% at 250A, 100% at 167A

- Feeder: 2 rollers, supporting 5kg spool

- Functions: brazing, inductance adjustment, pulse x3, possibility of aluminium welding in MIG, VRD, 2t/4T, IGBT

- Description: High quality semi-automatic welding machine which allows work in any method. The device is characterised by quality workmanship, high efficiency and many modern features which guarantee the highest quality of welding.

Did you like this product? Add to favorites now and follow the product.

Description

Welder Inverter Paton StandardMIG-250 – basic data

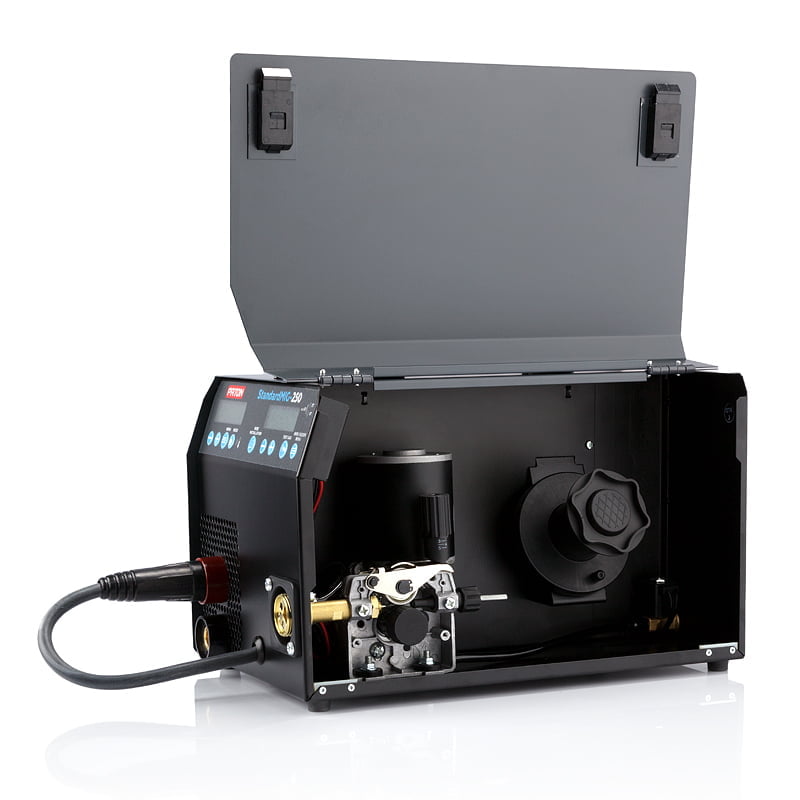

The Paton StandardMIG 250 MIG/MAG MMA/TIG Lift welder inverter is designed for semi-automatic MIG/MAG arc welding, gas shielded TIG arc welding and manual MMA arc welding with direct current (DC) with the possibility of using the PULSE function.

The “Standard” series is dedicated to home and semi-industrial use. StandardMIG 250 provides 45% duty cycle at full rated current of 250A without loss of productivity and work quality. Robust construction and simplicity of operation makes working with the device trouble-free, despite the small size of the welder, it allows you to obtain excellent weld quality. The use of the fully electronic control method in this series excludes the disadvantages that are characteristic of multifunctional systems. The welding source is set to optimal values, which allows you to start working with it right away. For more advanced work, the device is equipped with additional functions. A characteristic feature of PATON™ Standard series semi-automatic machines is a high-quality wire feeder, which has been additionally sealed, as well as the existing KZ-2 “EURO” type integrated connector, which has become a standard all over the world, allowing the user to choose any MIG/MAG torch according to his own preferences.

Functions and capabilities of the universal welder inverter Paton StandardMIG-250

GASLESS WELDING FUNCTION – WELDING WITH SELF-CONSUMING WIRE

All PATON MIG/MAG welding machines are adapted for welding with self-shielded wire. Such welding, as opposed to the traditional MIG/MAG welding process, is carried out without shielding gas – however, it requires a special welding wire. The wire produces its own shielding, which helps to protect the welding arc. Self-shielded wire suitable for PATON welding machines can be purchased here – 5 kg spools of wire will fit all wire feeders.

SOLDERING – INDUCTANCE ADJUSTMENT

Paton MIG/MAG welders of the Standard and PRO series have the possibility of brazing thanks to the function of changing the inductance in three stages. The inductance control enables to optimize the characteristics of the arc depending on the thickness of the component to be welded. This function is necessary to change the speed of the current flow when changing the arc voltage. The thinner the element to be welded with MIG/MAG, the higher the inductance should be (soft arc – less fusion), for thicker elements the opposite (hard arc – more fusion).

PULSE FUNCTION IN ALL METHODS

– PULSE in TIG welding – full control of heat entering the material – a great feature for welding stainless steel and acid-resistant steel,

– Pulses in MMA – easier transfer of material from electrode to weld pool, better quality of welded joint,

– Pulses in MIG/MAG welding – easier detachment of metal droplets from the end of electrode wire, possibility of pulse current adjustment. MIG welding with pulse is useful for welding stainless steel, acid-resistant steel and aluminum alloys. In addition, pulse welding provides better parameters for soldering CuSi3

THE MAIN DIFFERENCES BETWEEN MIG/MAG WELDING MACHINES OF STANDARD AND PRO SERIES:

- duty cycle – Standard Series MIG/MAG welders have a 45% duty cycle, while PRO Series has a 70% duty cycle at the same welding current. In addition, MIG/MAG welding machines in the PRO series achieve a continuous duty cycle at a higher welding current than MIG/MAG welding machines in the Standard series.

- Wire Feeder – The PRO Series has a separate wire feeder that handles spools from 15 to 18 kilos. The feeder can be separated from the source for convenience in welding other methods – such as MMA or TIG DC. The PRO Series also has 2 roll or 4 roll wire feeder versions. In MIG/MAG welding machines of the Standard series for 230V power supply, the wire feeder is built into the welder, supports only spools up to 5 kilo and always has two rolls.

Main advantages of the Paton StandardMIG-250 welder inverter:

- European manufacturing

- Electronic thermal protection system that protects all heat generating parts from overheating

- Reliability thanks to IGBT technology

- Possibility to work with long extension cables as well as with a generator

- Pulsed current welding in all welding methods

- Improved arc glow stability

- Change mode function 2T, 4T, gas cleaning with feeder function

- The devices have voltage spike protection and stabilization system, enabling proper operation in the voltage range of 160V to 260V

- Twice lower power requirements compared to traditional sources

- Optimum melting and correct stitch shape regardless of welding position

5-year manufacturer’s warranty for consumers and companies

The highest quality of workmanship confirmed by a 5-year DOOR-to-DOOR manufacturer’s warranty. STD series models feature a number of innovative design solutions that increase their reliability. These include a sealed and fail-safe wire feeder, a KZ-2 EURO type integrated connector and a built-in voltage stabilization module.

Purchased kit includes:

- Welder inverter PATON™ StandardMIG-250

- MIG MAG welding torch ABICOR BINZEL ABIMIG 3M

- Electrode holder 3m

- Mass holder 3m

- Wire feeder rolls 1x (0.6 – 0.8), 1x (1.0 – 1.2) V

- Quick connector for gas

- Cardboard packaging

- Operating instructions

Technical characteristics

| Rated power supply voltage 50/60 Hz | 230 V |

| Rated power supply current | 32 – 36 A |

| Rated welding current | 250 A |

| Maximum operating current | 335 A |

| Operating load factor % | 45% – 250 A 100% – 167 A |

| Power supply voltage range | 160 – 260 V |

| Welding current control range | 12 – 250 A |

| Welding current control range | 12 – 28 V |

| Wire feeding speed control range | 2,0 – 16 m/min |

| Diameter of a stick electrode | 1,6 – 6,0 mm |

| Number of pressure rolls | 2 |

| Diameter of electrode wire | 0,6 – 1,2 mm |

| Coil weight, not more than | 5 kg |

| Welding processes with a pulse welding mode | MMA: 0,2…500 Hz TIG: 0,2…500 Hz MIG/MAG: 5…500 Hz |

| Function “Hot-Start” | Adjustable |

| Function “Arc-Force” | Adjustable |

| Function “Anti-Stick” | Automatic |

| Reduction of open-circuit voltage | ON/OFF |

| Open-circuit voltage | 12 / 75 V |

| Welding arc starting voltage | 110 V |

| Rated consumed power | 6,9 – 7,7 kVA |

| Maximum consumed power | 9,3 kVA |

| Efficiency coefficient | 90% |

| Cooling | Automatic |

| Operating temperature range | –25 … +45 ºС |

| Fulfilled standards: | EN 60204 – 1:2006 EN 60974 – 1:2012 EN 60974 – 10:2014 |

| Overall dimensions (length, width, height) | 420 х 245 х 298 |

| Weight | 11,5 kg |

| Protection class* | IP 21 |

Downloads

Only logged in customers who have purchased this product may leave a review.

Related products

- Welding methods: MMA, MIG-MAG, TIG LIFT

- Welding current: 14A-270A, 400V power supply

- Warranty: 3 years, also for companies

- Duty cycle: 55% at 270A, 100% at 180A

- Wire feeder: 2 rollers, supporting 5kg, 15kg and 18kg spool

- Functions: brazing, inductance adjustment, pulse x3, possibility of aluminium welding in MIG, VRD, 2t/4T, IGBT

- Description: High quality semi-automatic welding machine which allows work in any method. The device is characterised by quality workmanship, high efficiency and many modern features which guarantee the highest quality of welding.

- Welding methods: MMA, MIG-MAG, TIG LIFT

- Warranty: 3 years, also for companies

- Duty cycle: 70% at 270A, 100% at 220A

- Wire feeder: 4 rollers, supporting 5kg, 15kg and 18kg spool

- Functions: brazing, inductance adjustment, pulse x3, possibility of welding aluminium in MIG, VRD, 2t/4T, IGBT

- Description: Professional semi-automatic welding machine which allows work in any method. The device is characterized by unrivalled quality of workmanship, high duty cycle and many modern features that guarantee the highest quality of welding.

- Welding methods: MMA, MIG-MAG, TIG LIFT

- Warranty: 3 years, also for companies

- Duty cycle: 70% at 270A, 100% at 220A

- Wire feeder: 2 rollers, supporting 5kg, 15kg and 18kg spool

- Functions: brazing, inductance adjustment, pulse x3, possibility of welding aluminium in MIG, VRD, 2t/4T, IGBT

- Description: Professional semi-automatic welding machine which allows work in any method. The device is characterized by unrivalled quality of workmanship, high duty cycle and many modern features that guarantee the highest quality of welding.

Welder Inverter MIG/MAG MMA/TIG Lift Paton ProMIG-500 (15-4) 400 V with water cooling

PRICE ON REQUEST- Welding methods: MMA, MIG-MAG, TIG LIFT

- Warranty: 2 years, also for companies

- Duty cycle: 70% at 500A, 100% at 420A

- Wire feeder: 4 rollers, supporting 5kg, 15kg and 18kg spool

- Features: brazing, inductance adjustment, pulse x3, aluminium MIG, VRD, 2t/4T, IGBT welding

- Description: A real welding machine with an integrated cooler and a high-quality trolley made of top quality metal. The device is characterized by unrivalled quality of workmanship, high duty cycle and many modern features that guarantee the highest quality of welding.

Arcent (Singapore) Pte Ltd

15 Yishun Industrial Street 1

#01-28 Win 5

Singapore 768091

UEN 201117183H

Need help? Call us:

Copyright 2024 © PATON Europe Sp. z o. o.

- Image

- SKU

- Rating

- Price

- Stock

- Availability

- Add to cart

- Description

- Content

- Weight

- Dimensions

- Additional information

Copyright 2024 © PATON Europe Sp. z o. o.

Reviews

There are no reviews yet.